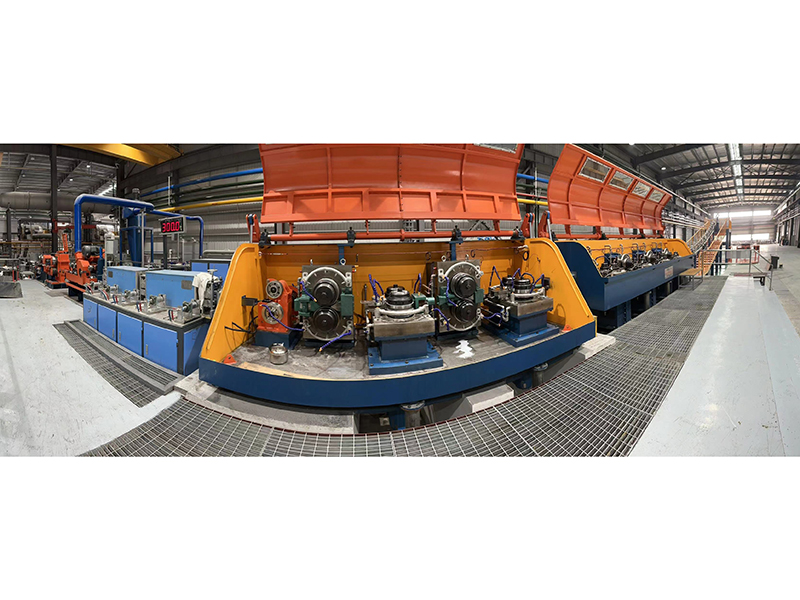

Aluminum Rod Continuous Casting and Rolling Line

CCR line for the production of aluminum and aluminum alloy conductors

This production line is mainly used for producing high-conductivity electrical aluminum rods with diameters of 9.5mm, 12.5mm, and 15mm, meeting European and American standards for EC1350 series, 3#, 5# (5005, 5154), 6# (6101/6201), and 8# (8176, 8030) series.

Features

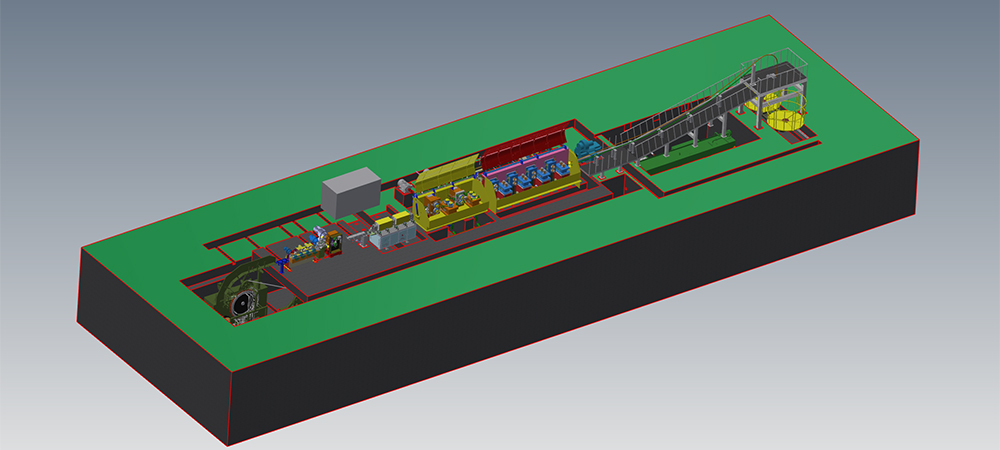

- The continuous casting and rolling line includes a four-wheel continuous casting machine, straightening machine, front tractor, rolling shear, optional medium-frequency heating furnace, clamping mechanism, continuous rolling mill, cooling system, rod collecting device, and electrical control system.

- The casting machine's crystallization wheel uses an H-shaped structure with four-sided cooling, ensuring dense and uniform ingots. The wheel diameter ranges from 1400-2300mm, depending on the product section, with cross-sectional areas from 1600-3300mm² based on production capacity.

- The medium-frequency heating furnace is optional, tailored to different product grades.

- The continuous rolling mill is available in three configurations: two-roll, three-roll, and a combination of two-roll and three-roll, chosen based on the aluminum rod grade.

- Production lines can be configured for different output capacities, with options for 4.5 tons/hour, 6.8 tons/hour, and 7.2 tons/hour to meet various production needs.

- The advanced electrical control system uses a programmable logic controller (PLC) and human-machine interface (HMI) to control and monitor the entire production line.

- Complete turnkey solutions are available, including pumps, filtration systems, heat exchangers, and emulsions to ensure seamless operation.

Specifications

| Model | Aluminum rod diameter (mm) | Roller diameter | Output (T/h) | Roller quantity | Optional configurations | Types of aluminum rod | ||

| Melting furnace capacity (T/h) | Holding furnace capacity (T) | Fuel | ||||||

5T | 9.5/ 12 /15 | 255/15-3 | 4.5-5 | 3 rollers | 6 | 10-15 | Natural gas, LPG, heavy oil, diesel, coal gas | 1xxx /6xxx /8xxx series |

6.8T | 9.5/ 12 | 320/2+255/14-3 | 5-6.8 | 2 rollers + 3 rollers | 12 | 20-25 | ||

7.2T | 9.5 /12 | 320/10-2 | 6-7.2 | 2 rollers | 12 | 20-25 | ||

Notes: the output mentioned above is the maximum value for 1xxx series aluminum rod of 9.5mm

Layout

Related Machines

Get in Touch