Tandem Extrusion Line

Cable extruder line for manufacturing building wires and cables

Discover our state-of-the-art tandem extrusion line at S&A, designed specifically for the production of building wires. With our advanced extrusion machinery, you can achieve efficient cable extrusion for various applications, including building cables and household cables.

Our VVF tandem extrusion line is a space-saving solution that combines three production lines, optimizing space utilization and reducing labor costs.

Features

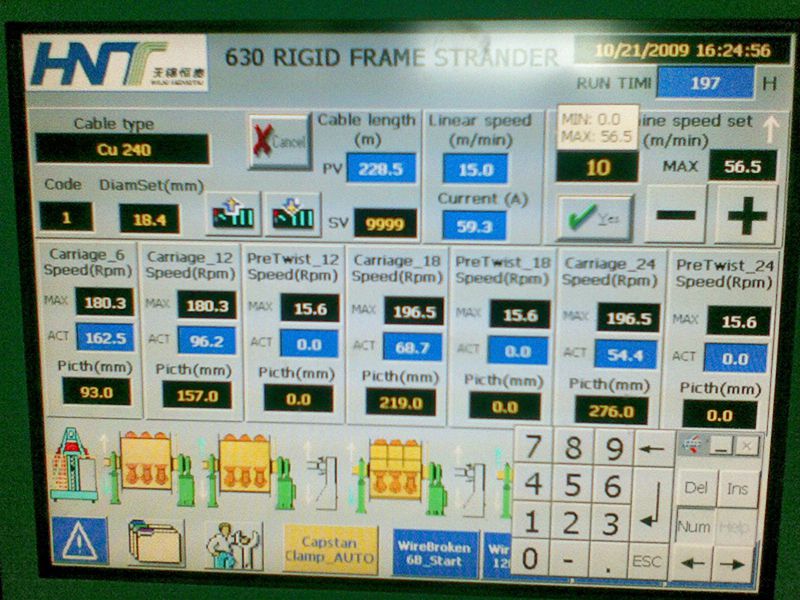

- PLC and Touchscreen Control: Our tandem extrusion line is equipped with user-friendly PLC and touchscreen controls, ensuring easy operation.

- Flexible Take-up Options: We offer various take-up options to suit your specific requirements.

- Convenient Configuration Storage: The PLC can store multiple cable specifications, allowing quick and easy setup when changing production specifications.

- Space-Saving Design: Our tandem extrusion line integrates three production lines into a single system, optimizing space utilization and reducing personnel requirements.

- Automatic Error Detection: The tandem extrusion line is equipped with an automatic error detection function, providing timely alerts to operators when issues occur.

Specifications

| Dia. Of copper (mm) | No. of cores | Thickness of insulation (mm) | Thickness of sheathing (mm) | Dia. Of product Short × long | length (m) | weight (kg/km) | Production speed (m/mi) | |

| 1.6 | 2 | 0.8 | 1.5 | 6.2 | 9.4 | 100 | 100 | 220.0 |

| 1.6 | 3 | 0.8 | 1.5 | 6.2 | 12.6 | 100 | 140 | 180.0 |

| 2.0 | 2 | 0.8 | 1.5 | 6.6 | 10.2 | 100 | 125 | 220.0 |

| 2.0 | 3 | 0.8 | 1.5 | 6.6 | 13.8 | 100 | 180 | 170.0 |

| 2.6 | 2 | 1.0 | 1.5 | 7.6 | 12.2 | 100 | 190 | 130.0 |

| 2.6 | 3 | 1.0 | 1.5 | 7.6 | 16.8 | 100 | 275 | 130.0 |

Details

Pay-Off

- Frame-Type Pay-Off: This type of pay-off utilizes a gantry-style framework, allowing copper cores to be pulled from the inner side and smoothly guided through the collector frame and steering pulleys.

- Cantilever Pay-Off: With electrically controlled lifting and pneumatic clamping, the cantilever pay-off provides secure and efficient wire feeding. It is equipped with safety devices such as upper and lower limit switches.

Take-Up

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading of wire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stoppage after machine shutdown

Horizontal Accumulator

- Seamlessly integrated with the extrusion line, enabling fully automated processes.

Meter Counter

- Non-contact electronic meter counter for accurate and reliable measurements

- Mechanical meter counter included

Control System

- Siemens PLC control for smooth operation and reliable performance

- All technical parameters adjustable via the touchscreen interface, with the ability to store production process parameters

Related Machines

Get in Touch