PV Solar Cable Extrusion Line

Cable extruder line for photovoltaic wire insulation

Enhance your photovoltaic wire production with S&A PV Solar Cable Extrusion Line.

Our PV solar cable extrusion line is specifically designed for the extrusion of photovoltaic wires, catering to wire sizes ranging from 4 mm² to 6 mm².

Features

- Our PV solar cable extrusion line utilizes high-quality screws and barrels made in Taiwan, delivering superior extrusion performance and reliable output.

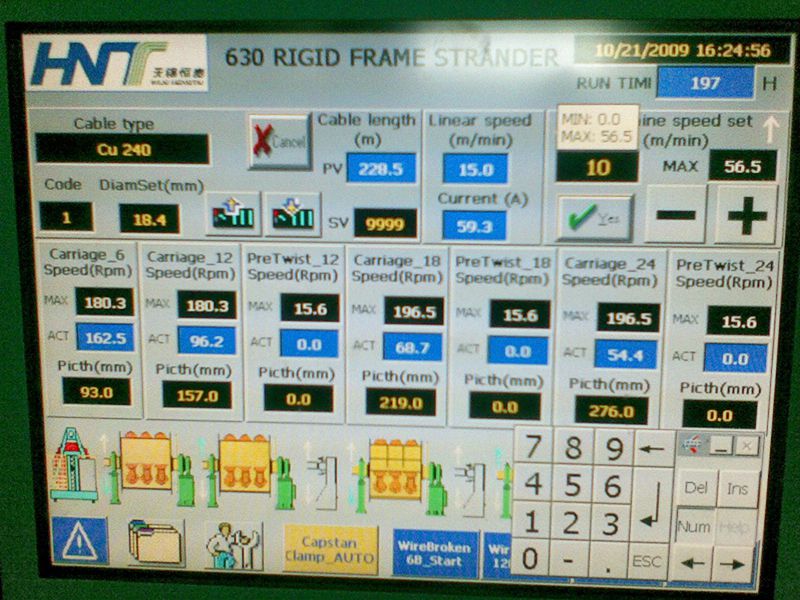

- The entire production line is controlled by Siemens S7-1500 PLC combined with the KTP1200 Siemens touchscreen interface. Real-time production line status monitoring enables efficient process management.

- Precise temperature control is achieved using temperature controllers from the Japanese RKC series and solid-state relays (SSRs), ensuring consistent and accurate extrusion.

- Our cable extrusion machinery features both automatic and manual control modes. The main extruder and traction unit can be operated in synchronization or independently. It also allows for nonlinear curve correction of extrusion volume, while the traction unit can operate in both independent and synchronized modes.

- The HMI and PLC control system enables easy modification, storage, and adjustment of wire diameter, detection, line speed, spark detection, and other process parameters through the user-friendly touchscreen interface.

Specifications

| Machine type | Ø70 | Ø90 | Ø80 + Ø90 | 80+100 |

| Screw diameter | Ø70 mm | Ø90 mm | Ø80 + Ø90 mm | 80+100 |

| Extrusion amount | 140 kg/h | 350 kg/h | 350 kg/h | 500 kg/h |

| Applicable material | PE, XLPE and etc. | |||

| Control mode | Touch screen + PLC | |||

| Max line speed | 300 m/min | 300 m/min | 200 m/min | 200 m/min |

| Wire diameter control precision | ±0.02 mm | |||

Details

Pay-Off

- Our PV solar cable extrusion line is equipped with a high-speed drum-type pay-off system, ensuring efficient and reliable wire feeding.

Take-Up

- The dual-reel take-up system allows for efficient and time-saving wire collection and storage.

Meter Counter

- Non-contact electronic meter counter for accurate and reliable measurements

Control System

- Dual-Mode Control: Our cable extrusion machinery offers both automatic and manual control modes. The main extruder and traction unit can operate in synchronization or independently, providing versatile production capabilities.

- HMI+PLC Control: The HMI and PLC control system allows convenient modification, storage, and adjustment of wire diameter, detection, line speed, spark detection, and other process parameters through the touchscreen interface.

Related Machines

Get in Touch